How We Work

Our company delivers LED display solutions through a structured,

end-to-end process designed to ensure technical accuracy, visual excellence, and long-term reliability.

From the initial inquiry to final commissioning and ongoing support,

every stage is managed by experienced specialists to guarantee a smooth and successful project delivery.

1. Inquiry and Order Request

The process begins when a client contacts us with an inquiry or project requirement. At this stage, we collect essential information, including:

Application type (signage, videoboard, scoreboard, architectural LED, etc.)

Indoor or outdoor environment

Approximate screen size and resolution

Viewing distance and usage purpose

Location details and project timeline

This allows us to understand the client’s objectives and technical constraints before moving forward.

2. Consultation and Technical Assessment

Our technical team reviews the project requirements and provides professional consultation. This includes:

Selecting the appropriate LED technology and pixel pitch

Recommending suitable screen type and configuration

Assessing environmental conditions (brightness, weather exposure, humidity)

Advising on control systems, software, and integration requirements

At this stage, we may request drawings, photos, or conduct a site review (remote or on-site) to ensure accurate planning.

3. Solution Design and Specification

Based on the assessment, we develop a tailored LED solution. This includes:

Screen dimensions and resolution

Cabinet and module configuration

Structural and mounting design

Power and data layout

Control system and software setup

Detailed technical specifications, layouts, and system architecture are prepared to ensure clarity and approval before production.

4. Commercial Proposal and Order Confirmation

We present a detailed commercial proposal outlining:

Equipment specifications

Scope of work

Installation requirements

Project timeline

Warranty and service terms

Once approved, the order is formally confirmed, and the project moves into production planning.

5. Production and Quality Control

All LED components and systems are manufactured and assembled according to the approved specifications. This phase includes:

Component sourcing and assembly

Module and cabinet testing

Brightness and color calibration

Signal and power stability testing

Quality inspections at multiple stages

Only fully tested and verified systems proceed to delivery.

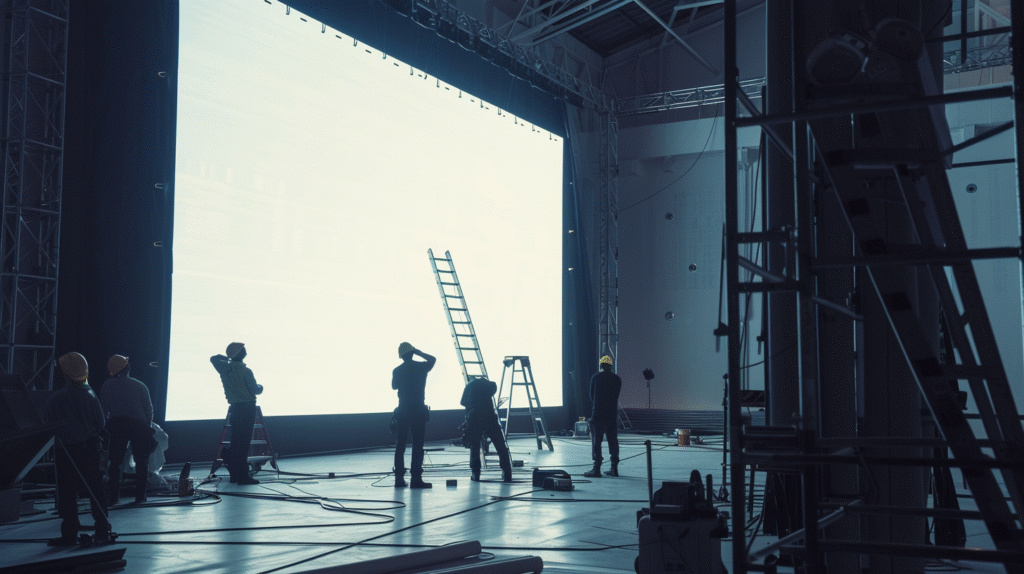

6. Pre-Installation Planning and Site Scaling

Before installation, we prepare the site in detail. This includes:

Reviewing structural load and mounting points

Measuring and scaling the installation area

Verifying power supply and data access

Coordinating access, safety requirements, and scheduling

Accurate scaling ensures the LED screen fits precisely within the intended space and performs optimally.

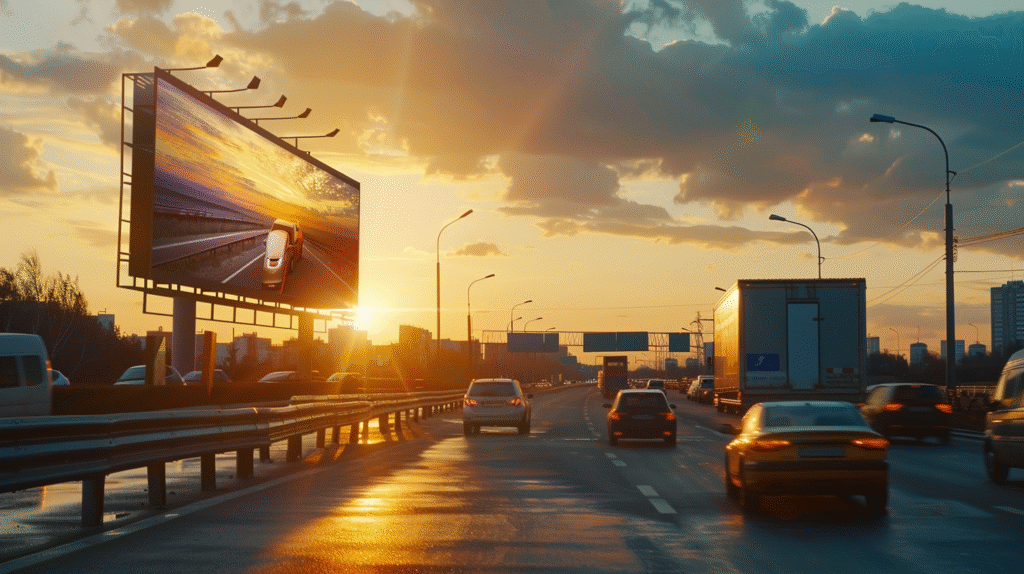

7. Delivery and On-Site Installation

Our installation team handles:

Mechanical structure assembly

LED cabinet and module installation

Power and data connections

Safety checks and alignment

Installations are carried out following industry standards and site-specific safety regulations.

8. System Configuration and Commissioning

Once installed, the system is fully configured and tested on-site. This includes:

Screen mapping and pixel alignment

Brightness and color calibration

Control system and software setup

Content testing and signal verification

The LED screen is commissioned only after meeting performance and quality benchmarks.

9. Client Training and Handover

We provide training for the client’s technical or operational staff, covering:

Content management

System operation

Basic troubleshooting

Maintenance best practices

All relevant documentation and system credentials are handed over at this stage.

10. After-Sales Support and Maintenance

Our responsibility continues after installation. We offer:

Warranty support

Remote diagnostics

Software updates

Spare parts availability

Technical assistance and maintenance services

This ensures long-term performance, reliability, and customer satisfaction.